In nature, lightning usually comes from thunderstorms. But physicists in research institutions also like to dabble with producing these electric discharges. As, for example, in the high-voltage lab at the University of Applied Sciences in Kiel, which carried out a particularly spectacular test on behalf of KLINGER Kempchen: a lightning current test of its semi-metallic gaskets.

Contacts mentioned in the article:

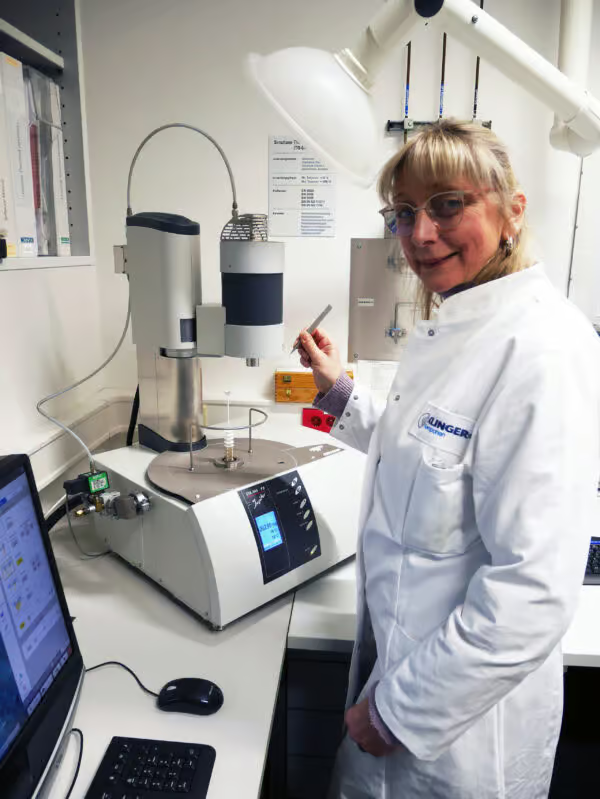

Michael Buchholz, Head of the physics and chemistry lab at KLINGER Kempchen

“Gas pipes, and therefore the metal gaskets they are sealed with, may well sustain lightning strikes. We need to be sure that the resulting high electrical current will not damage the gaskets if this happens,” says Michael Buchholz, who heads the physics and chemistry lab at KLINGER Kempchen. Lightning current tests falls into the realm of physics: Simulating the enormous natural force of a lightning strike requires both special apparatus and expertise in handling the dangerously high voltages it generates. The high-voltage lab at Kiel University of Applied Sciences ticked both of these boxes.

Patron of power

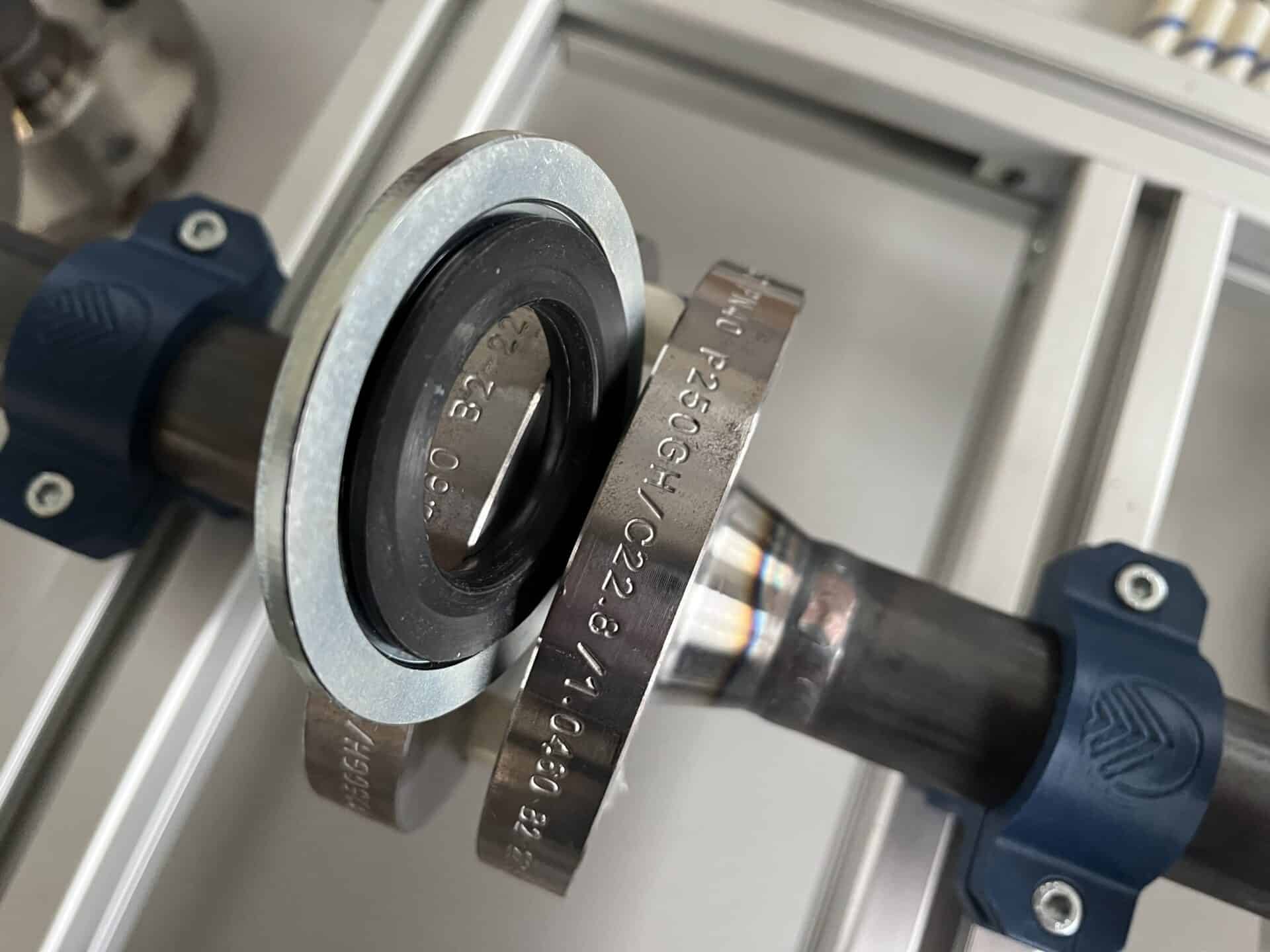

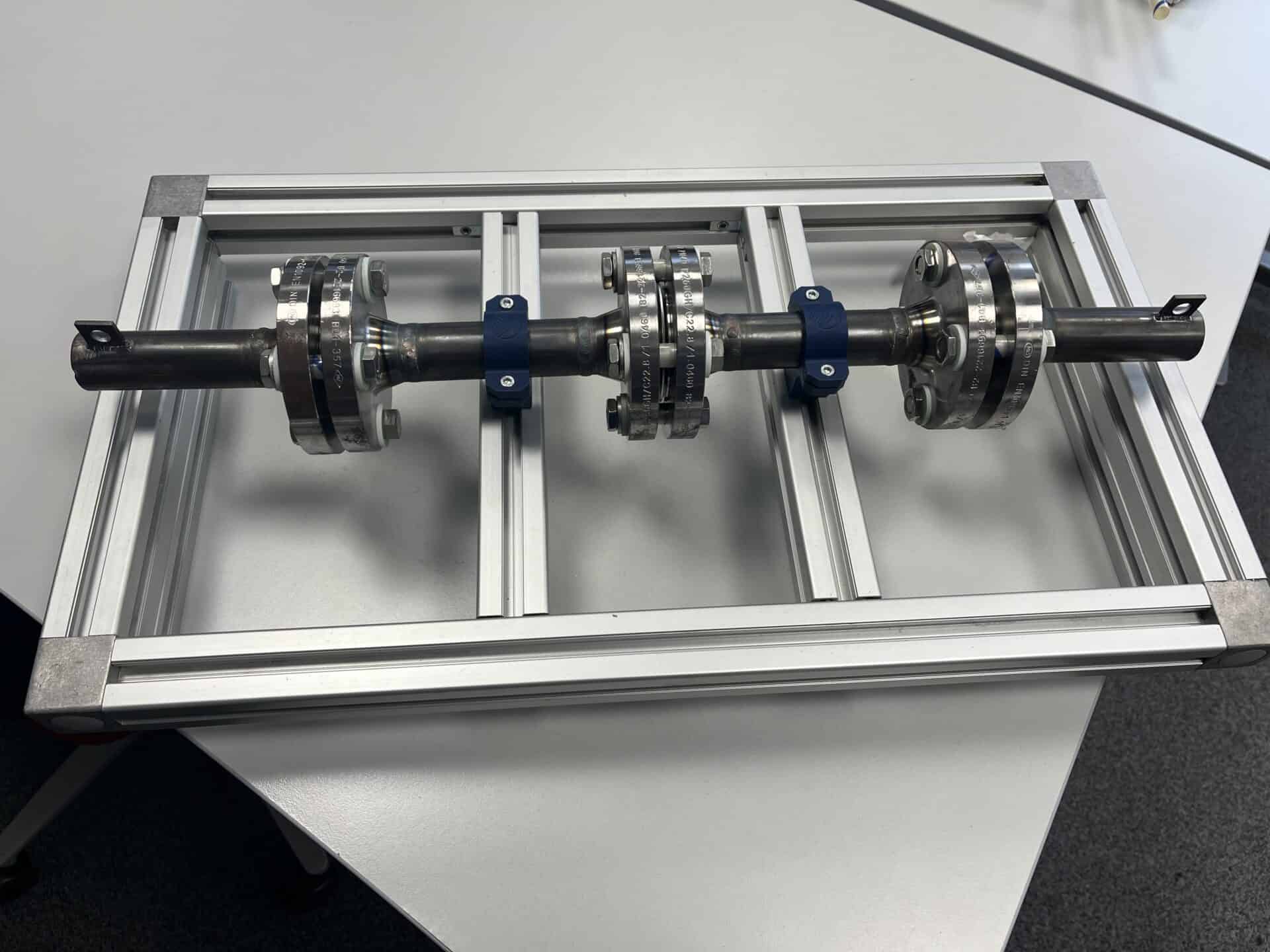

As well as teaching and research, the high-voltage lab’s activities includes preparing lightning protection reports for industry partners. For KLINGER Kempchen, the lab conducted testing in accordance with DIN standard 30691:2024-12 for lightning current tests on flanges with conductive gaskets. The test fixture consisted of three pairs of welding neck flanges (DN25/PN40) welded in series via a connecting pipe. The following seals passed the test with flying colors:

- B45A-GR Ø 36 / 52 x 71 x 4.90 mm

- W1A-3-GR Ø 34 / 63 x 71 x 3.0 mm

- KNG-galvanized Ø 34 / 57 x 71 x 4.75 mm

Michael also included detailed assembly instructions with the description of the test setup: “To obtain a realistic result, it was important for the flanges to be assembled correctly. We wanted to test whether our gaskets conduct electricity well enough to withstand high voltages without damage and remain tight,” says the long-serving KLINGER Kempchen employee, who has been with the company for over 40 years and began his career there as a technical draftsman. As a trained mechanical engineer, he appreciates the variety of tasks his job entails, which always includes new and exciting aspects – such as lightning current testing.

Lightning strike survived?

The spectacular, albeit brief, test – each of the three lightning currents is applied for just a few tenths of a second – was captured on video. The slow-motion footage shows how the 75 kiloampere current pulses cause sparking at the flanges, accompanied by a loud bang. The extreme energy of the pulse heated the test setup by around 10 °C with all the gaskets that passed. Before the subsequent leakage test – the actual purpose of the undertaking – could be carried out, the setup had to cool back down to ambient temperature.

“The second part of the test, the leakage test, was done with nitrogen at a pressure of 16 bars. A pressure gage was used to record the rate of pressure drop. The pressure stayed constant, indicating that the gaskets survived the lightning strike,” says Michael, pleased with the result. The fact that the tested KLINGER Kempchen semi-metallic gaskets exhibited a very low resistance of only 0.1 milliohms is also positive. Their excellent conductivity means that the gaskets do not impede the flow of current at the flange connection. Nor did a visual inspection of the gaskets after the lightning current test reveal any damage:

“We couldn’t rule out the possibility of the high current causing the carrier rings of the corrugated profile to fuse to the flange. But that wasn’t the case.”

Michael Buchholz, Head of the physics and chemistry lab at KLINGER Kempchen

Michael also had to smile at the report from the lab that a gasket was found to be “completely broken” after a flange connection was opened. But the photo showed that only the graphite coating was destroyed during disassembly. This is completely normal when removing a compressed gasket, as Michael knows thanks to his many years’ experience with gaskets. So, he says: “they were also able to learn something new about gaskets in the university lab.”

Fact box

Did you know…

… that a lightning strike in the wild can pack a current of several hundred kiloamperes?

… that lightning consists of four to five main discharges on average that last only up to three tenths of a second?

… that there are various different forms of lightning, such as bead lightning, ribbon lightning and anvil lightning?