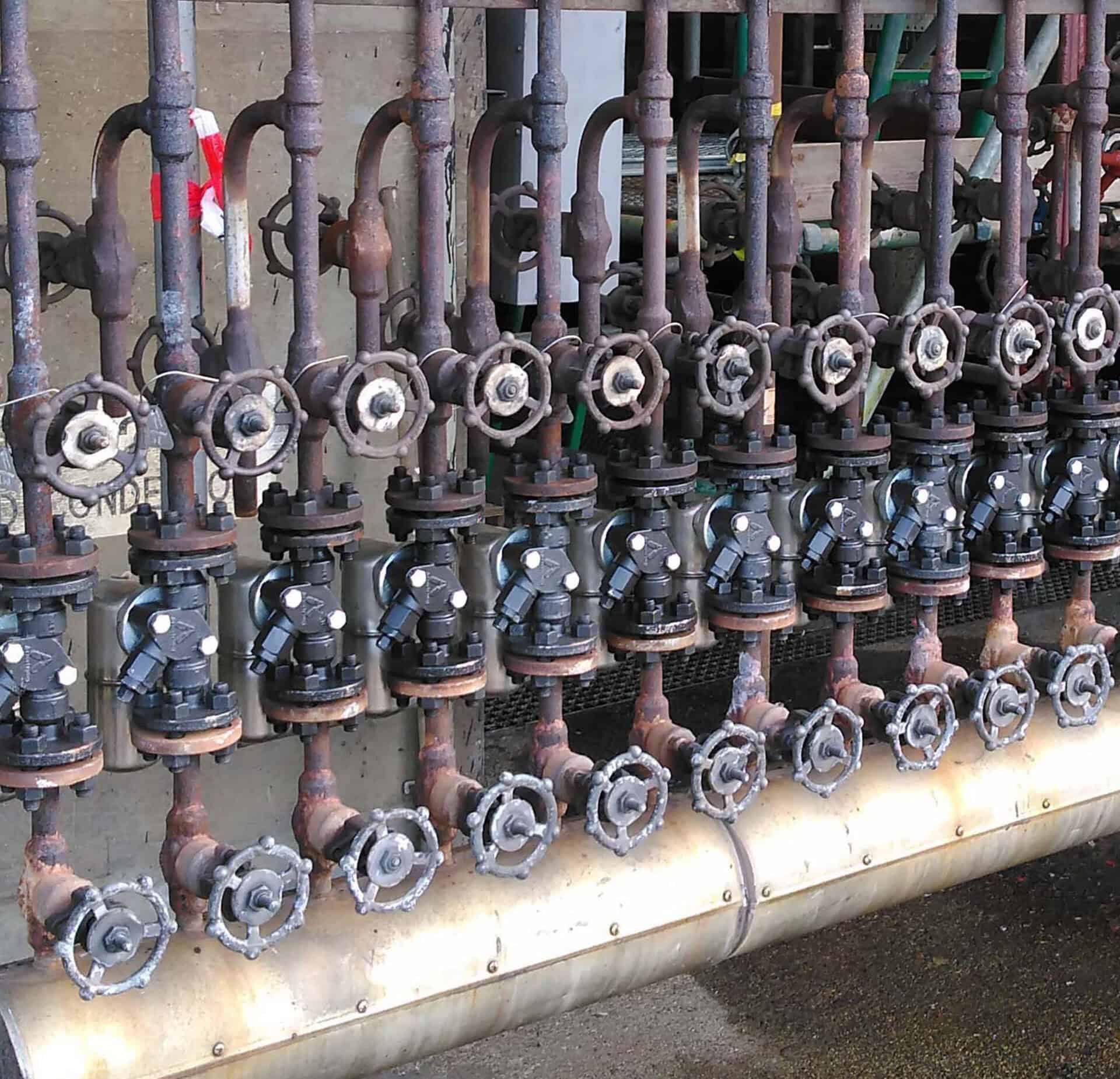

The bp Rotterdam refinery is one of Europe’s largest and most advanced oil refineries. Here, crude oil is processed into a wide range of products, including gasoline, diesel, kerosene and basic chemicals essential for various industries. Steam and condensate systems are crucial in the refining process. Steam is used for various purposes, including keeping pipes at temperature, powering turbines and in the process to strip light components from heavier components. KLINGER The Netherlands plays a decisive role in the maintenance of the bp Rotterdam refinery’s steam and condensate systems. With their technical expertise, they help the refinery operate efficiently and safely, contributing to the facility’s overall performance and sustainability.

Copyright: Edwin Kotylak / bp

The challenge

With an ever growing need to save energy in the process industry, bp has been proactively improving its steam and condensate system in recent years. It has done so by preventively measuring steam trap function, (internal) leakage and plugging. Leaking steam traps result in (internal) steam leaks, which cause water hammer, increased condensate back pressure and higher operational costs (fuel & CO2). Plugged steam traps lead to significant problems such as reduced heat transfer, pipe corrosion and erosion in process equipment . These two failure mechanisms increase maintenance and operational costs by causing many steam leaks in the production units. There was a need at the refinery to improve predictability and proactively replace steam traps even before it caused visible operational problems. This underlines the importance of regular maintenance and inspection to ensure safe and reliable operation of industrial plants.

The solution

In 2022, bp Rotterdam and KLINGER The Netherlands sat down together to develop a new preventive maintenance strategy for the bp refinery’s steam traps. After ten years of only performing corrective maintenance when problems became visible, a comprehensive survey was conducted on three assets to assess the condition of each of the steam traps. This analysis revealed that a significant number of steam traps were leaking or just plugged highlighting the need for the steam trap survey conducted by the Dutch KLINGER subsidiary. These inspections on the three assets were the starting point for a major corrective maintenance program aimed at replacing and modernizing the existing steam traps.

“As well as increasing operational efficiency, the steam traps strategy also improved safety.”

Dennis Pedersen, Reliability Engineer at bp

The result

Replacing and upgrading leaking and plugged steam traps has reduced the number of visible steam leaks at the refinery. This, in turn, has reduced maintenance costs, as fewer pinholes occur that require the use of clamps. It has also resulted in a more stable process within the refinery. Moreover, operating costs have been reduced due to lower fuel consumption and CO2 emission costs. As well as increasing operational efficiency, the steam trap strategy has improved safety by eliminating slipping hazards – in winter from freezing condensate, and in summer from algae growth caused by condensate leaks.